Track Electrolab’s history and success over the following decades.

Electrolab, Inc. Established

Karl Senghaas, Founder of Electrolab

1976

Electrolab was founded in 1976 in San Antonio, Texas, by Karl Senghaas, a German-born electrical engineer and NASA scientist.

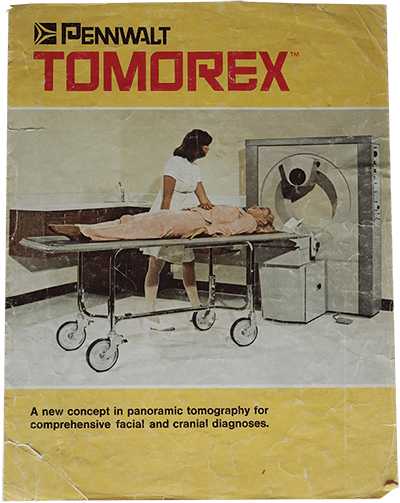

Mr. Senghaas (1922 – 2012) was a long-standing contributor to the engineering and technology industry in San Antonio and held numerous patents for his designs. Mr. Senghaas’ design contributions included engineering patents that involved UTSA, an institution near and dear to his heart. Mr. Senghaas led the design and implementation of the first solid state interconnection of 500 dental offices at University of Texas Health Science Center (UTHSC) in the seventies. Later, Mr. Senghaas played a key role as lead in electronics design, working together with UTHSC’s design team, to patent the first “Tomerex” X-Ray machine used for full-mouth X-Ray scans.

Mr. Senghaas’ engineering contributions spanned many industries, including beverage and food service, aviation, oil & gas, and water management. Mr. Senghaas also worked with NASA teams on the development of the Photomultiplier used in space-exploration. With companies calling on Electrolab to design electronics technologies that others would not attempt, Karl Senghaas was often lovingly named “The Einstein of San Antonio”. International firms recognized his unique approach to electronics design and his unrelenting desire to find creative solutions to problems that initially appeared unsolvable. Throughout his career, Mr. Senghaas never forgot to train young engineers, providing countless opportunities for growth and achievement right here in San Antonio.

In 2013, Electrolab established the the Karl Senghaas Engineering Scholarship at UTSA, which is awarded each year to a student of Electrical Engineering.

Providing Innovative Solutions for Clients

Tomorex Product

1980

1982

1985

1987

1988

Entering the Oil & Gas Industry

Model 1000 Level Sensor

1992

1992

1993

1996

1999

A New Era for Electrolab

Circa 2008, Electrolab Facility with new logo signage, San Antonio, TX

2007

2008

Expanding Product Offerings

Grouping of Stainless Steel, Fiberglass and Flexible Level Sensors

2010

R&D for Surface Protection Chemistry Begins (Precursor to e9 Treatments)

- Focus on Repelling Paraffin and Asphaltenes on Digital Level Sensors

2011

Initial Planning for New Facility in Boerne Begins

Goals:

- Increase Manufacturing Space

- Increase Product Development / R&D

- Build ISO 9 White Room for Electronics Manufacturing

2012

Digital Level Sensor – Model 2100 Digital Level Sensor Released

Land Acquired for New Facility in Boerne, Texas

Initial Surface Protection Chemistry (Anti-Paraffin Treatment) Developed – Field Testing Begins

2013

Siemens Private Label Agreement Ends (Not Renewed by Electrolab)

- Electrolab Hires Sales and Marketing Team

- Electrolab Establishes Distribution Channel for Oil & Gas Products

- Electrolab Sells Oil & Gas Products under Electrolab Brand

- All Steel Products Treated with Anti-Paraffin Treatment

2014

Groundbreaking Event for New Manufacturing Facility in Boerne Occurs in May

New Facility Construction Begins (32,500 s.f.)

Digital Level Sensor – DLS Guide Tool Released

First product application of anti-paraffin treatment.

2015

Digital Level Sensor – Flexible Level Sensor R&D Begins

Construction of new facility in Boerne, TX completed

Grand Opening Event Held for New Facility in Fall – 300+ Attend

TankChek Released

2016

Digital Level Sensor – RU Flex (Flexible) Digital Level Sensor Released for Field Trial

e9 Treatments, Inc. is Incorporated

Digital Level Sensor – Stainless Steel Sensor with High-Level Shut-In Released

Digital Level Sensor – New Intrinsically Safe Barrier Devices Released

2017

All Electrolab Digital Level Sensors Meet API 18.2 Compliance

Patent# 9688926 Issued

Digital Level Sensor – Fiberglass Sensor with High-Level Shut-In (HLS) Released

2018

Digital Level Sensor – Explosion Proof Housing Packages for Digital Devices Released

Digital Level Sensor – RU Flex Model 2100 (Flexible Level Sensor) Released

All Level Sensors Released with High-Level Shut-In (HLS) Option

Patent# 10059892 Issued

Patent# 10150924 Issued

2019

Expanded manufacturing facility with addition of Building 2 (3750 s.f.)

IoT Product Family Initial Development – Energy Monitoring and Control (IRIS Family)

More product releases and updates

Explosion Proof Housing Packages for Both Digital and Analog Devices

2020

Patent Assignments for Surface Treatment Products Transferred to e9 Treatments, Inc.

Patent#’s 10822559 and 10844299 Issued.

2021

Digital Level Sensor – Separator Package Released

Patent# 10934497 Issued

2022

TempSens™ Released for Rail Cars

Temperature measurement probe designed for hazardous locations. TempSens offers C1D1 certification is ideal for accurate measurement of liquid materials being loaded and unloaded from rail cars at the depot.

Explosion Proof Housing for Analog Devices Released

Simplifies site design and meets electrical code without the need for additional equipment.

RediLevel™ Model 2100 DLS

Smaller Profile Level Sensor for Two-inch Ports

2023

Harsh Environment Float

3-D printed nylon float ideal for caustic and corrosive chemicals and other harsh liquid/gas environments. Available on rigid sensors and RediLevel.